Insects and birds sing, spring water sings and sounds, and the sound originates from the vibration of objects. It is a well-known thing that the human ear can recognize sound waves with a vibration frequency of 20Hz~20kHz. However, multi-layer Chip Ceramic Capacitors (MLCC) sometimes makes a acoustic noise. What is going on?

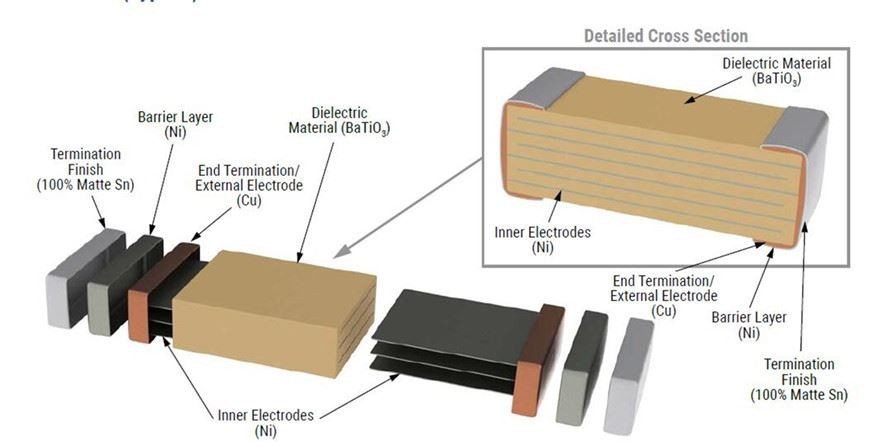

Multi layer ceramic capacitors (MLCC) are made of ceramic medium and metal inner electrode which are superposed in a staggered way. After one-time high-temperature sintering, the ceramic chip is formed, and then the outer electrode metal layer is sealed at both ends of the chip. The dielectric material system of this kind of ceramic capacitor is mainly divided into two types: I ceramic dielectric and II ceramic dielectric.

I ceramic dielectric belongs to paraelectric medium (the main materials are SrZrO3, MgTiO3, etc.), and I ceramic dielectric will not produce electrostrictive deformation. Therefore, MLCC made of I ceramic dielectric material, such as ceramic capacitor with CG characteristics, will not produce acoustic noise when working, but the dielectric constant of this kind of medium is very small, usually between 10 ~ 100, so it is unable to produce large capacitance capacitor.

Type Ⅱ media belong to ferroelectric media (the main material is BaTiO3, BaSrTiO3, etc.), and ferroelectric materials will produce electrostrictive deformation. MLCCs made of type II dielectrics, such as X7R, X5R, etc., usually have a dielectric constant between 2000 and 4000, and the capacitance of the capacitor is relatively large, and it is easy to produce obvious howling noise under the action of a specific AC signal.

Why does MLCC have acoustic noise

In order to better understand the nature of capacitor acoustic noise, let's first understand a natural phenomenon-the piezoelectric effect.

In 1880, brothers Pierre Curie and Jacques Curie discovered that tourmaline has piezoelectric effect. In 1984, the German physicist Wodemar Voith deduced that only crystals with 20 point groups without a symmetry center could have the piezoelectric effect. The piezoelectric effect is due to the special arrangement of atoms in the crystal lattice of the piezoelectric material, which makes the material have the effect of coupling the stress field and the electric field.

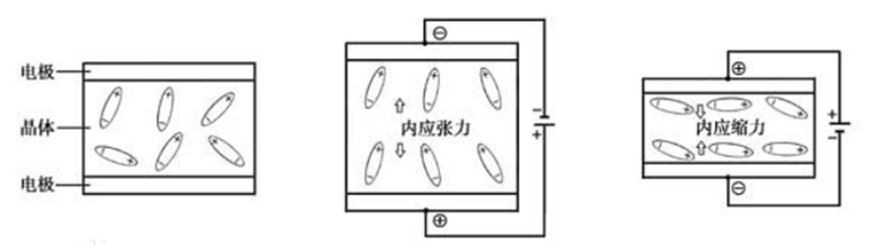

The academic definition of the piezoelectric effect is: when certain dielectrics are deformed by external forces in a certain direction, polarization will occur inside them, and at the same time, positive and negative charges will appear on its two opposite surfaces. When the external force is removed, it will return to an uncharged state. This phenomenon is called the positive piezoelectric effect. When the direction of the force changes, the polarity of the charge also changes. On the contrary, when an electric field is applied to the polarization direction of the dielectric, these dielectrics will also deform. After the electric field is removed, the deformation of the dielectric disappears. This phenomenon is called the inverse piezoelectric effect, or electrostriction. These two positive and inverse piezoelectric effects are collectively referred to as piezoelectric effects. The piezoelectric effect is a phenomenon in which mechanical energy and electrical energy are exchanged in dielectric materials.

Obviously, the MLCC capacitor acoustic noise we are discussing belongs to the category of inverse piezoelectric effect. More generally speaking, under the action of an external electric field, the ferroelectric ceramic medium with piezoelectric effect will undergo expansion and contraction. This kind of expansion and contraction is called electrostriction. The electrostrictive properties of different ceramic media are also different. For other types of capacitors, because the dielectric material does not have a piezoelectric effect, or the piezoelectric effect is minimal, the howling on the circuit is basically due to the vibration generated by the inverse piezoelectric effect of the ferroelectric ceramic medium MLCC.

(Picture source network)

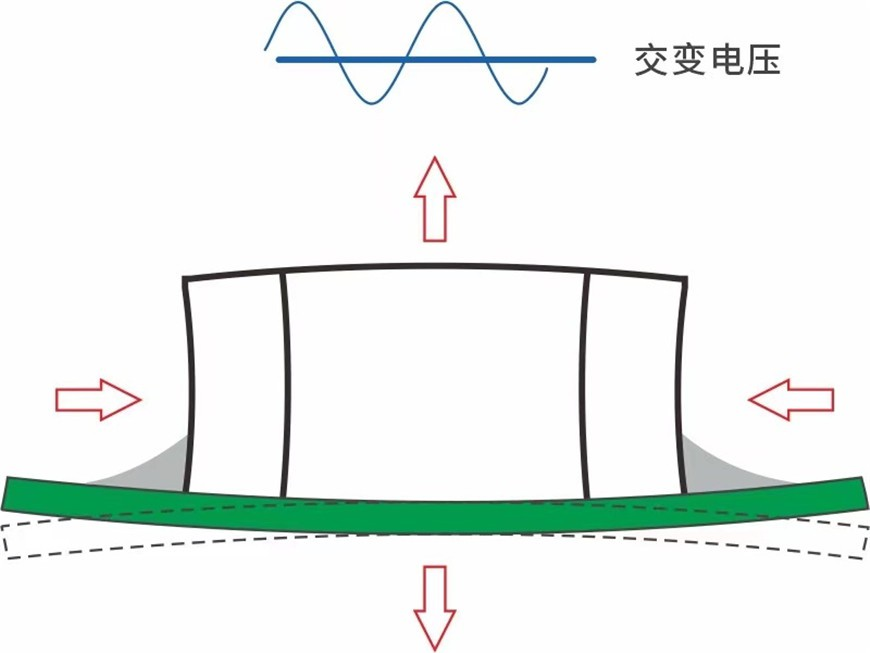

As shown in the figure above, the ferroelectric ceramic medium's ferroelectricity will produce piezoelectric effect noise. The general Poisson’s ratio (transverse deformation coefficient) of MLCC dielectrics is about 0.3. After an AC signal is applied, multilayer ceramic capacitors will stretch and deform in the direction parallel to the stacking direction and the circuit board, and the resulting amplitude is usually pm to nm level. When it is not soldered to the circuit board, the acoustic impedance of a single capacitor is different from that of the air, but if this is the case, it should be almost inaudible. When the ceramic capacitor is soldered on the circuit board, the capacitor and the circuit board are rigidly connected, and the deformation of the capacitor will pull the circuit board. The circuit board becomes an acoustic impedance transformer. When the vibration frequency reaches the distinguishable frequency band (20Hz~20kHz) of the human ear, then, you will hear acoustic noise .

On what occasions does MLCC have acoustic noise

In common audio circuits, especially audiophiles, people usually like to use ruby, black diamond and other electrolytic capacitors. Because the working frequency of the audio circuit is usually relatively low, such as several kHz or tens of kHz, and the ferroelectric ceramic capacitor may produce a whistling sound that can be heard by the human ear at this working frequency. This effect will be lost at frequencies much higher than 30kHz, because the capacitor itself cannot respond quickly to change the pressure level. Therefore, the peak response range and noise characteristics determine that these capacitors should be used with caution in audio circuits and high gain circuits.

Under the action of specific AC signals, MLCCs using ferroelectric ceramic dielectrics (such as X7R/X5R) may produce howling. The violent howling comes from violent vibration, and the amplitude of the vibration is determined by the degree of the piezoelectric effect, which is proportional to the intensity of the electric field. When the applied voltage is constant, the thinner the medium, the stronger the piezoelectric effect and the louder the howling sound.

What is the impact of MLCC acoustic noise

Due to the existence of capacitive howling, when mobile electronic devices are close to human ears, the audible noise generated by electronic products (laptops, tablets, smart phones, etc.) will affect the user's feelings, and violent howling will make people feel irritable .

Under an alternating electric field, the ferroelectric domains of ferroelectric ceramic capacitors will alternately turn as the direction of the electric field changes, causing friction within the ferroelectric domains and increasing the probability of failure of the capacitor. In addition, the appearance of capacitor whistling also indicates that the voltage ripple on the capacitor is too large. Severe voltage ripple will affect the normal operation of the circuit and cause the circuit to work abnormally.

How to solve MLCC acoustic noise

There are many ways to solve the howling noise generated by MLCC capacitors, and the solution may increase the cost.

1. Changing the type of capacitor dielectric material is the most direct method. Use Class I ceramic capacitors, film capacitors, tantalum electrolytic capacitors, aluminum electrolytic capacitors and other capacitors that do not have piezoelectric effect instead. However, issues such as volumetric space, reliability, and cost need to be considered.

2. Adjust the circuit to eliminate the alternating voltage applied to the MLCC as much as possible.

3. Adjust the specifications and layout of the PCB circuit board to reduce vibration and help reduce the level of howling.

4. Adjust the size of MLCC.

5. Use MLCC with no noise or low noise.

Based on this, for the MLCC product itself, we can adopt the following solution strategies

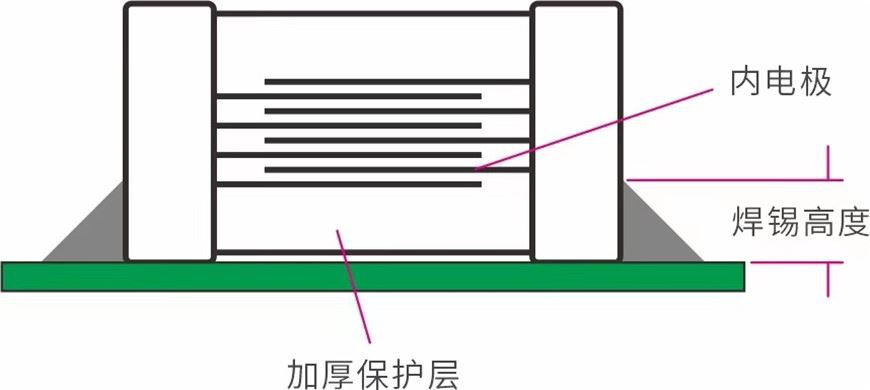

(1) Thicken the protective layer. Since the thickness of the protective layer has no internal electrodes, this part of the BaTiO3 ceramic will not be deformed. When the solder height at both ends does not exceed the thickness of the bottom protective layer, the deformation generated at this time will have less impact on the PCB, which can effectively reduce noise.

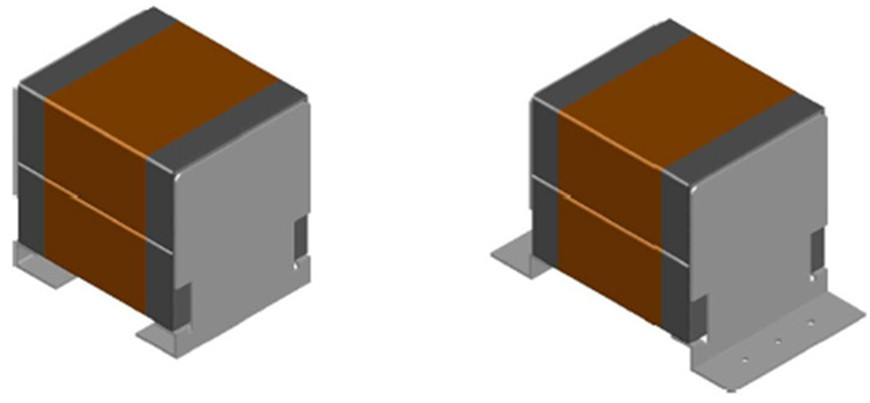

(2) Additional metal support structure. The structure diagram of the bracket capacitor is as follows. It uses a metal bracket to isolate the MLCC chip from the PCB board. The inverse piezoelectric effect produces deformation and elastically buffers the metal bracket to reduce the effect on the PCB board, thereby effectively reducing noise.

(3) Adopt lead product structure. The principle is similar to that of the metal bracket.

(4) Design and manufacture using dielectric materials with weak piezoelectric effect. By further doping barium titanate (BaTiO3) to sacrifice a certain dielectric constant and temperature characteristics, a dielectric material with greatly reduced piezoelectric effect is obtained, and the MLCC made with it can effectively reduce noise.

(5) Substrate embedded design. A new structure with capacitors mounted on the interposer circuit board is adopted to suppress howling.

Conclusion

Based on the acoustic noise phenomenon of MLCC capacitors, combined with the structure of the chip ceramic dielectric capacitor and the characteristics of the ceramic dielectric material, we analyzed the howling mechanism of ferroelectric ceramic dielectric capacitors, and finally enumerated the solutions and strategies to solve the howling phenomenon. . In different application scenarios, engineers in the electronics field need to weigh the cost and actual effects and choose the best solution to develop better products.