1. Avoid external force

(1) During the assembly process, PCB must be avoided to meet too strong or too fast bending.

(2) Ceramic chip capacitors are designed to avoid high mechanical stress when the circuit board is bent, as shown in below Figure.

(3) The two solder joints of ceramic chip capacitor should be designed and mechanically bonded. The direction of stress is balanced and not at right angles, as shown in below Figure.

(4) At the connector connection between the cable and PCBA, if the circuit board is not supported when the connector is pulled out or inserted, the circuit board will warp and damage the nearby components. When the area of circuit board is large (i.e. greater than 15 cm × 15 cm), special care should be taken to prevent damage to components.

2. Selection of materials

In order to improve the thermal matching between the chip capacitor and the substrate material, it is necessary to select the appropriate substrate material and the capacitor with higher level and better resistance to thermal stress and mechanical stress to meet the requirements of product use.

3. Welding requirements

When welding, the operator should strictly implement the process discipline and carry out welding according to the process documents and typical process requirements.

4. Design requirements

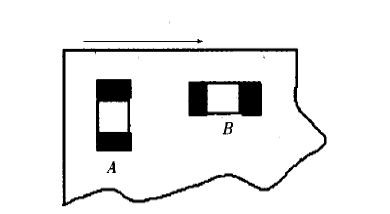

The pad spacing should be reasonable. The design in below Figure(a) is easy to be damaged due to stress after the chip capacitor is welded. below Figure (b) design helps to improve resistance to mechanical stress.

(2) When designing PCB, designers should design pad according to enterprise standard to avoid unreasonable design.

5. Repair requirements

When it is necessary to repair the capacitor, considering the effect of welding heat accumulation, the capacitor after welding should be discarded and new capacitor should be used.

6. Conclusion

Correct operation method, reasonable material selection and correct pad design can play a very good role in reducing the failure of capacitor, improving product quality and reliability, and avoiding unnecessary rework.