i. Storage Precautions

Moisture sensitivity level(MSL):MSL3

Storage Conditions:

Temperature:-5~40°C, Humidity: ≤60%RH

Free of corrosive gases. After removing the vacuum package, the capacitor should not be exposed to the air for more than 24 hours. Unused capacitors should be vacuum sealed again or stored in a dry cabinet.

ii. Precautions before Soldering

Tantalum capacitors can be attached by wave soldering, reflow soldering and hand soldering. Case A, B, C, D, D1, and E are recommended to use reflow soldering (if hand soldering is required, please see 2. Precautions for Hand Soldering Operations), and Case F and above are only suitable for hand soldering (large case tantalum capacitor is reflowing soldered, due to the expansion of the core, it is very easy to have cracks in case.).

1. Baking Treatment

For CA55 capacitor that has been unpacked and exposed to the air for more than 24 hours, the user must remove tape before use and perform secondary baking at a humidity ≤ 60% RH to ensure that there is no excessive moisture absorbed inside the capacitor before soldering . The recommended baking temperature and time are:

a. For CA55 capacitor that has been unpacked and exposed to the air for more than 24 hours, it is recommended to bake at 125°C for 12 hours before soldering.

b. For CA55 capacitor that has been unpacked and exposed to the air for more than a week, Case A, B, C, D1, D, and E need to be baked at 125°C for 24 hours; Case F and above are only suitable for hand soldering, and no need to bake before soldering.

2. Hand Soldering

capacitors that are hand soldered do not require baking before soldering, but the temperature of the soldering iron tip should be strictly controlled. It is recommended to use a soldering temperature of 280-350 ℃ (30W power soldering iron, anti-static ceramic electric soldering iron is recommended). At the same time, it should be noted that:

a. It is prohibited to directly use a soldering iron tip to heat the element substrate. Because excessive temperature shock can cause damage to the internal microstructure of the component, leading to performance issues.

b. The solder pad must be pre-printed with solder paste, and the thickness of the solder paste should be controlled between 0.15mm and 0.20mm.

c. It is necessary to use a circuit board heater to preheat the bonded components at least 125 ℃~150 ℃/5 minutes, ensuring that the temperature of the component substrate is as close as possible to the melting point of the solder paste.

d. The position of the soldering iron tip for soldering heating is the solder pad, not the component substrate.

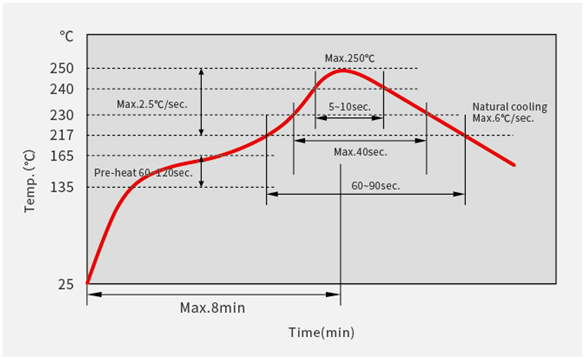

3. Reflow soldering

The reflow soldering curve is suitable for Case A, B, C, D, D1, E:

Lead-free capacitors: the maximum soldering temperature is 250±5°C

Leaded capacitors: the maximum soldering temperature is 235±5℃